What is Recycled Nylon Fabric?

Recycled nylon fabric is an innovative material produced from post-consumer waste, such as old fishing nets, fabric scraps, and other nylon-based products. This process not only diverts waste from landfills and oceans but also significantly reduces the need for virgin nylon production, thereby conserving resources and energy.

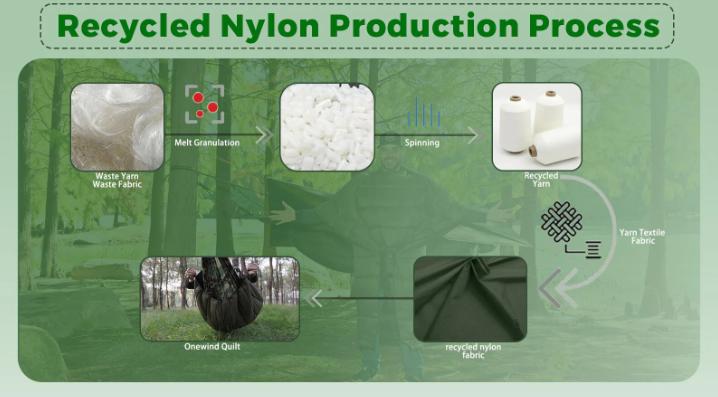

The Recycled Nylon Production Process

The production process of recycled nylon involves several key steps that transform waste materials into high-quality fabric. Here’s an overview of how recycled nylon is created:

Collection of Waste Yarn and Fabric: The journey begins with the collection of waste yarn and fabric, which are the primary raw materials for recycled nylon. These waste materials are sourced from various post-consumer and industrial waste streams.

Melt Granulation: The collected waste is then subjected to melt granulation, a process that involves melting the nylon waste to form granules. This step is crucial as it prepares the material for spinning by converting it into a workable form.

Spinning: The nylon granules are then spun into recycled yarn through a meticulous spinning process. This yarn retains the high strength and durability characteristics of virgin nylon, ensuring the quality of the final product.

Yarn Textile Fabric: The recycled yarn is woven into fabric, creating a versatile and sustainable material that can be used in various applications. This step completes the transformation from waste to fabric.

Final Product: The recycled nylon fabric is then utilized to create various products, such as outdoor gear, clothing, and accessories, exemplifying the practical and eco-friendly use of recycled materials.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt