Pirelli was the first to produce an FSC (Forest Stewardship Council) certified tire that uses natural rubber and FSC rayon. As a result, customers had the guarantee that all materials sourced from forests came from plantations that promote biological diversity while bringing economic sustainability to the lives of local communities and workers.

The main challenge in developing the new P Zero E was to combine the need for sustainability with the high performance required from a UHP tire. This objective was reached thanks to these new materials, which include:

Lignin comes from the scrap of the pulp and paper industry. Lignin contributes to tire durability and foreseen rolling resistance reduction.

Rice husk ash silica derives from the scrap of rice cultivation. Silica is widely used in tread compounds to obtain a high level of performance in wet conditions. Rice husk ash silica is a good replacement for fossil-based silica in such tread applications.

Circular carbon black for tires derives from end-of-life tire pyrolysis oil. Pyrolysis is a way to prevent landfill disposal of end-of-life tires. Carbon black is used in rubber compounds to optimize the stability, strength, and durability of tires.

Bio-circular polymers are made from monomers derived from used cooking oils or tire pyrolysis oil. They are a replacement for fossil-sourced polymers.

Natural rubber tyres are obtained from the latex of Hevea Brasiliensis, the rubber tree. This is a material 100% derived from biomass.

Bio resins are plasticizers deriving from vegetal biomass such as plant seeds (sunflower or canola) or forest-based resins. Bio resins are versatile ingredients, providing a better balance of dry and wet performance.

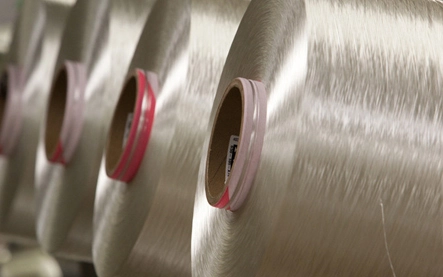

Rayon is a textile reinforcement of a tire, with fibres deriving from cellulose.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt