In the realm of tire manufacturing, the quality and durability of the materials used play a pivotal role in ensuring road safety, performance, and longevity. Among the various components that contribute to the strength and resilience of tires, the construction of the tyre cord fabric is of paramount importance. Dipped nylon tyre cord fabric, in particular, stands out as a superior choice, embodying a combination of strength, flexibility, and endurance that significantly elevates the performance of tires.

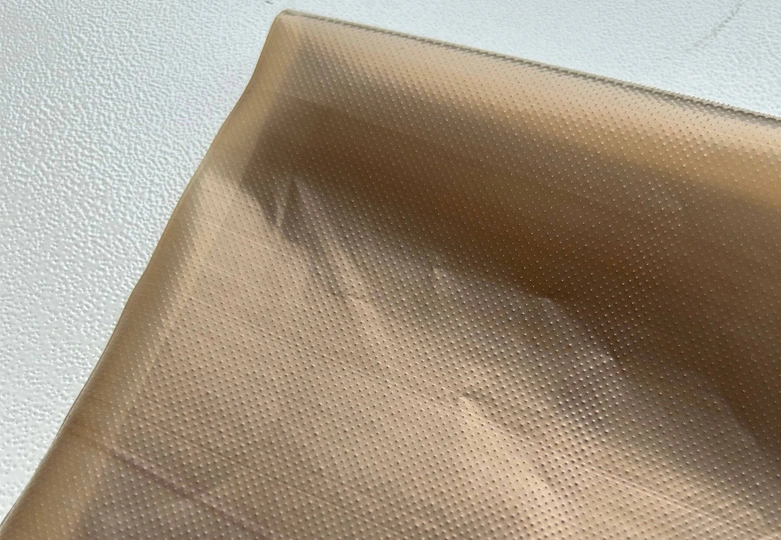

At the core of every tire's structure lies the tyre cord fabric, acting as the foundation of its strength and durability. Dipped nylon tyre cord construction involves weaving nylon fibers into a fabric, which is then immersed or "dipped" in a special compound to enhance its performance characteristics. The inherent strength of nylon fibers, known for their high tensile strength and resistance to abrasion, sets the stage for the superior durability and load-bearing capabilities of the resulting tyre cord fabric.

The dipped process further reinforces the nylon threads, creating a fabric that not only withstands the rigorous conditions of the road but also provides excellent dimensional stability. This dimensional stability is crucial in maintaining the structural integrity of the tire, ensuring consistent performance under varying conditions.

In addition to its robust strength, dipped nylon tyre cord fabric brings a unique advantage in terms of flexibility. The weaving process allows for a controlled interlacing of nylon threads, creating a flexible yet resilient fabric. This flexibility is essential for tire manufacturers as it enables the tyre cord fabric to conform to the shape of the tire during the manufacturing process.

The flexibility of dipped nylon tyre cord construction is not only beneficial during tire production but also plays a crucial role in the tire's performance on the road. It enhances the tire's ability to absorb shocks and impacts, contributing to a smoother ride and improved handling. The dynamic interaction between the flexible tyre cord fabric and the tire's overall structure ensures optimal performance across a range of driving conditions.

The dipped nylon tyre cord fabric's superiority extends to its endurance on the road, where tires are subjected to a multitude of challenges. The special compound in which the fabric is dipped enhances its resistance to heat, moisture, and environmental factors. This resistance is particularly critical in preventing the degradation of the tyre cord fabric over time.

Moreover, the dipped nylon construction contributes to the tire's ability to resist fatigue and tread separation, two common issues that can compromise safety and performance. The reinforced structure of dipped nylon tyre cord fabric ensures that tires maintain their integrity, even under the harshest conditions, promoting longevity and reliability.

In conclusion, the superiority of dipped nylon tyre cord construction lies in its ability to combine strength, flexibility, and endurance. The meticulous weaving and dipping process result in a tyre cord fabric that forms the backbone of durable and high-performance tires. As automotive technology continues to advance, the importance of superior materials, such as dipped nylon tyre cord fabric, becomes increasingly evident in the quest for safer, more efficient, and longer-lasting tires on our roads.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt