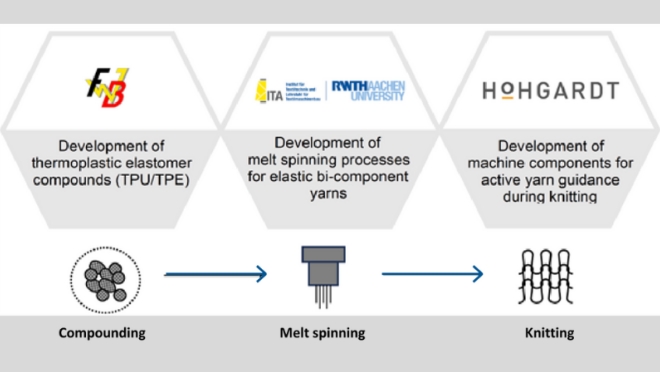

In general, elastanes are mainly made from segmented elas-spinning process. However, the use of melt-spinnable alterna-tomeric polyurethanes (PUR). Due to the cross-linking proper-tives to elastomeric PUR has not yet become established in ties of elastomeric PUR polymers, elastane yarns are produced market-ready products, especially yarns. Although it has already almost exclusively by solvent-based dry spinning, which poses been possible to spin TPU yarns at realistic production speeds particular challenges. The production process of dry spun in previous research projects, the developed TPU yarns still yarns often requires the use of toxic solvents such as dimethy- show a high surface tackiness. This surface tackiness makes it lacetamide (DMAC), which can be harmful to health. Although difficult to unwind the yarns from the bobbins and to produce most solvents are recovered during yarn production, it is gen-textile fabrics by weaving and knitting. To reduce the tackiness, erally desirable to avoid their use in textiles due to residual the "RÖKO-Band" project is pursuing the approach of a bi-com-amounts in the yarns. In addition, the production speed of dry ponent yarn made of TPU and TPE.spinning processes is limited, whereas melt spinning processes can reach production speeds of up to 7,000 m/min, depending.The project consortium consists of 3 partners covering the on the polymer entire textile process chain with their expertise. The project is divided into three sub-areas, which are targeted by the individual.To overcome these challenges, thermoplastic elastomers or project partners. FBW GmbH, Niederzier/Germany, is responsi-polyurethanes(TPE or TPU) can be used instead of elastomericble for the development of sweat-resistant,thermoplastic PUR, as these can be processed into filament yarns in a melt elastomer compounds(TPU and TPE) for sports applications.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt