Osaka, Japan – Teijin Frontier has developed an ultra-fine polyester staple fiber (Nanofront™ staple fiber) as an effective rubber reinforcement.

Short fibers are commonly used as a reinforcing fiber to increase the rigidity of rubber. Ultra-fine polyester staple fiber is an ultra-fine polyester fiber whose “island” component functions as a reinforcing fiber. By using polyethylene that is compatible with rubber for the “sea” component, there are benefits that include good dispersibility within rubber compounds when kneaded with the rubber at a certain (or higher) temperature.

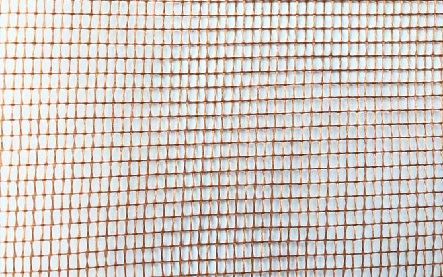

Since the ultra-fine staple polyester tyre cord fabric features an extremely small diameter (700 nm and 400 nm), it provides a high aspect ratio and excellent dispersibility in rubber compounds, making it possible to effectively improve the mechanical properties of rubber, particularly the elastic modulus.

In addition to the effect of improving the elastic modulus, Teijin Frontier has also confirmed that a composite containing the ultra-fine polyester staple fibers has a low coefficient of friction, and the amount of wear is minimal.

From an environmental perspective, it has been confirmed that this ultra-fine polyester staple fiber can securely provide a high rubber reinforcement effect without a bonding treatment to the rubber. As a result, it is comparable to high IVPET reinforced short fiber. Teijin Frontier, one of the leading tire cord fabric suppliers in this sector, estimates that the carbon footprint is about half that of typical rubber reinforcement materials, and the company also believes this technology can contribute to a reduction in the environmental impact of rubber reinforcement.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt